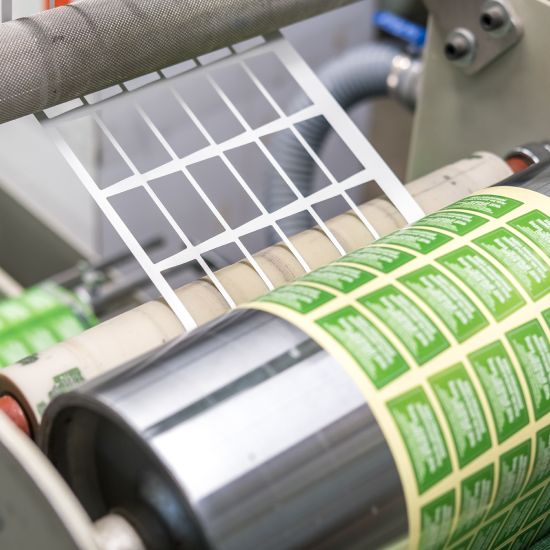

AI-Powered Label Inspection Solution Transforms Quality Control with Automated Precision

Manual label inspection often leads to errors, slowdowns, and inconsistencies, risking print quality and disrupting production timelines. This AI-driven label inspection solution redefines quality control by automating the inspection process on high-speed production lines with unmatched precision and efficiency. Leveraging high-resolution cameras and advanced computer vision algorithms, the system instantly detects print defects, misalignments, and incorrect or missing label data in real time. By eliminating manual checks, it ensures consistent quality, accelerates production throughput, and reduces costly errors — empowering manufacturers to maintain high standards without compromising speed.

Technology Used

Machine Learning algorithm Computer Vision

Techniques include CNNs, object detection, anomaly detection

AI & Machine Learning Engineering

Expertise in developing and deploying machine learning models using CNNs, R-CNNs, and anomaly detection techniques for real-time defect identification.

Computer Vision Solutions

Building vision-based systems using advanced image classification and object detection frameworks to detect smudges, misprints, incorrect labels, and missing information.

High-Speed Processing & Edge AI

Delivering optimized models for GPU/TPU acceleration and edge computing, enabling high-speed image inspection that matches industrial production rates.

Seamless Industrial Integration

Integrating AI inspection solutions with production lines, MES, PLCs, and SCADA systems for end-to-end automation and minimal production disruption.

Automated Quality Control Workflows

Engineering systems for real-time automated defect detection, report generation, and quality dashboards for operational teams.

Data Annotation & Continuous Learning

Providing labeled datasets, training pipelines, and continuous model improvement with new production data.

We’d love to learn more about your goals and how we can help. Share your details, and we’ll be in touch shortly.

Thank you for reaching out to NetWeb.